You are about to explore the detailed world of airplane gearboxes. They are key to aircraft operation. An airplane gearbox is a complex system essential for an aircraft’s function.

gearbox working

It’s vital to grasp how gearbox working mechanisms work. This is true for anyone in aircraft maintenance, repair, or operation. The aircraft transmission system is critical for the aircraft’s performance.

Key Takeaways

- Understanding airplane gearboxes is key for aircraft maintenance and operation.

- The gearbox is vital for an aircraft’s function.

- Aircraft transmission systems are essential for performance.

- Knowing gearbox working mechanisms is vital for repair and operation.

- Airplane gearboxes are complex systems needing deep understanding.

Understanding Aircraft Gearboxes

To understand aircraft gearboxes, you need to know what they are, why they’re important, and how they came to be. An aircraft gearbox is key. It sends power from the engine to the propeller or rotor. It changes the speed and torque to make the aircraft work better.

Definition and Purpose of Aircraft Gearboxes

An aircraft gearbox is a mechanical system. It changes the speed and torque of power from the engine to the propeller or rotor. Its main job is to make sure the engine’s power is used well. This helps the aircraft work well in different conditions.

aircraft gearbox

Historical Development of Aviation Gearboxes

The aviation gearbox history shows big steps forward. From simple gears to complex transmissions, the journey has been about making gearboxes better. Early gearboxes were simple. But as aircraft got more advanced, so did the gearboxes.

| Era | Gearbox Development | Key Features |

| Early Aviation | Simple Gear Systems | Basic gear ratios, limited power handling |

| World War II | Advanced Gear Systems | Improved durability, increased power handling |

| Modern Era | Complex Transmission Systems | High efficiency, sophisticated control systems |

The Fundamentals of Gearbox Working in Aircraft

The basics of how gearboxes work in planes are all about mechanical principles. Knowing these principles helps us see how important gearboxes are for planes to work right.

Basic Mechanical Principles

Gearbox design uses a few key mechanical ideas. These include gear ratios, how torque is sent, and controlling speed. Gear ratios change the engine’s speed for different plane parts. Torque transmission makes sure power gets to the propeller or rotor well. These mechanical ideas are key for planes to run well.

Power Transmission in Aircraft Systems

Power in planes moves from the engine to parts like propellers or rotors. The gearbox is key in this, adjusting speed and torque for each system. Good power transmission is vital for planes to perform well and efficiently.

aircraft gearbox power transmission

Torque Conversion and Speed Regulation

Torque conversion and speed regulation are what the gearbox does best in planes. It changes the engine’s fast, low-torque output to slow, high-torque for propellers or rotors. This lets planes work well in many conditions. By controlling speed and torque, the gearbox helps planes perform at their best.

To wrap it up, gearboxes in planes rely on mechanical basics, good power flow, and precise torque and speed control. Getting these points is key to understanding how vital gearboxes are for planes to operate smoothly.

Types of Aircraft Gearboxes

Aircraft gearboxes are made for different needs in various planes. You’ll learn about main, accessory, and tail rotor gearboxes in helicopters. Each has its own role and use.

Main Reduction Gearboxes

Main reduction gearboxes slow down the engine’s fast speed to a propeller-friendly pace. They’re key in turboprop planes and some helicopters.

In turboprop engines, these gearboxes lower the turbine’s high RPM to a better speed for the propeller. This speed is usually between 1,000 to 2,000 RPM.

Accessory Gearboxes

Accessory gearboxes power aircraft accessories like generators and pumps. They’re driven by the engine and give the needed power.

These gearboxes are built to be small and efficient. They often handle more than one task in one unit.

Tail Rotor Gearboxes in Helicopters

Tail rotor gearboxes are special in helicopters. They power the tail rotor. This is key to keeping the helicopter steady and on course.

These gearboxes handle the stress of tail rotor work. They give the mechanical boost needed.

| Type of Gearbox | Primary Function | Application |

| Main Reduction Gearbox | Reduce engine RPM to propeller/rotor speed | Turboprop engines, some helicopter configurations |

| Accessory Gearbox | Drive aircraft accessories (generators, pumps) | Various aircraft types |

| Tail Rotor Gearbox | Drive the tail rotor | Helicopters |

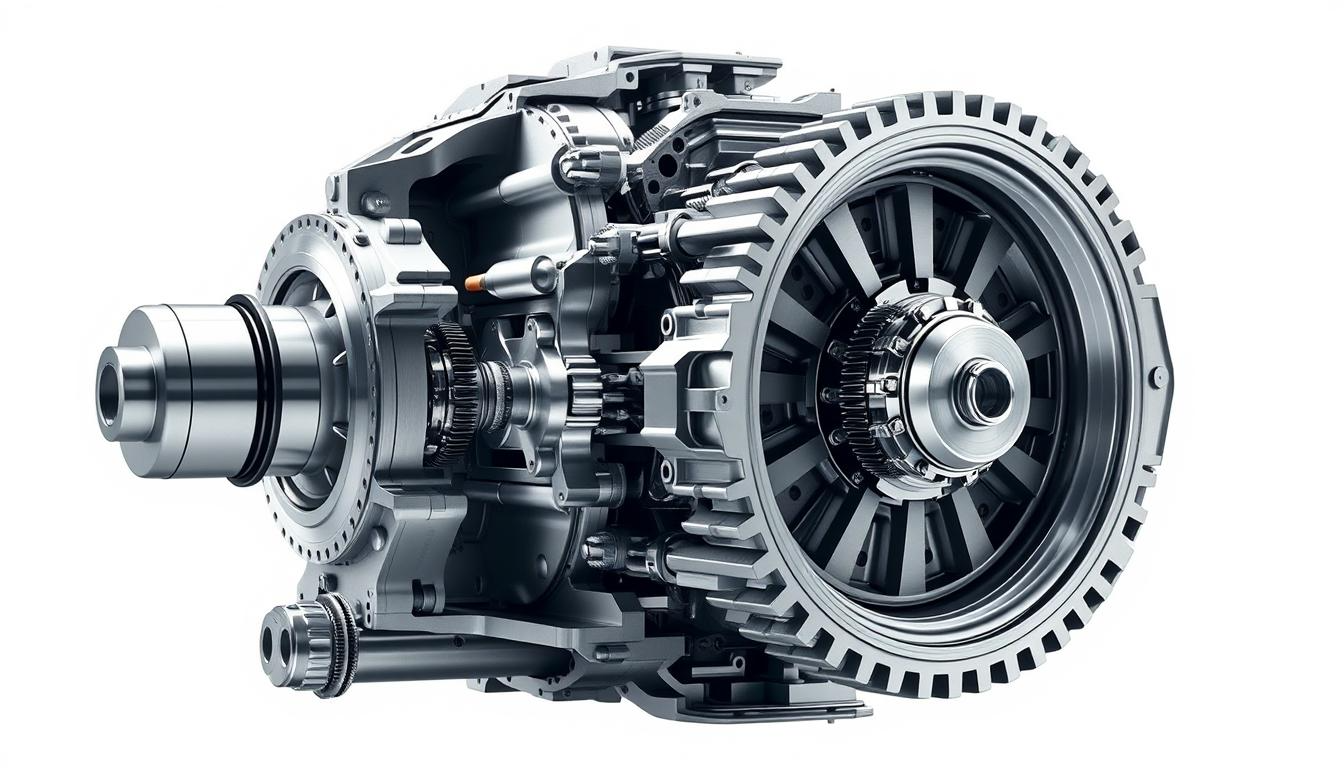

Components of an Aircraft Gearbox System

Knowing the parts of an aircraft gearbox is key for good maintenance and repair. The gearbox is complex. It needs all its parts working well to transmit power and control it.

Gears and Gear Arrangements

Gears are essential for an aircraft gearbox. They help move power from the engine to the propeller or rotor. There are different gears like spur, helical, and bevel. They work together to change the gear ratio and torque.

Bearings and Lubrication Systems

Bearings are vital for the gearbox. They support the gears and shafts, making them rotate smoothly. A good lubrication system keeps the bearings and gears running well. It reduces wear and prevents overheating.

Housing and Mounting Structures

The gearbox’s housing protects its parts from damage. It keeps the gears, bearings, and lubrication system safe. The mounting structures hold the gearbox in place. They help reduce vibration and stress on the gearbox and other parts.

| Component | Function | Importance |

| Gears | Transmit power | High |

| Bearings | Support gears and shafts | High |

| Lubrication System | Reduce friction and wear | High |

| Housing | Protect internal components | High |

Understanding the parts of an aircraft gearbox shows how complex and vital these systems are. They ensure safe and efficient flying.

Gearbox Working Mechanisms in Different Aircraft Types

Different aircraft types have unique gearbox working mechanisms. The design and operation of gearboxes vary across commercial airliners, military aircraft, and helicopters. Each is tailored to their specific needs and operational requirements.

Commercial Airliners

Commercial airliners use high-efficiency gearboxes for smooth and quiet operation. These gearboxes handle high torque and provide reliable power transmission. For example, the geared turbofan engine in some aircraft has a gearbox that reduces fan speed for more efficient operation.

A comparison of gearbox characteristics in commercial airliners is shown in the table below:

| Aircraft Type | Gearbox Type | Gear Ratio |

| Boeing 737 | Planetary Gearbox | 3:1 |

| Airbus A320 | Spur Gearbox | 2.5:1 |

| Boeing 787 | Geared Turbofan | 4:1 |

Military Aircraft

Military aircraft need gearboxes that can handle high-stress conditions and provide rapid power transmission. These gearboxes are designed to be highly reliable and work well under extreme conditions. Afterburner systems in some military jets also use advanced gearbox designs to manage increased power output.

Helicopters and VTOL Aircraft

Helicopters and VTOL aircraft use complex gearbox systems. These manage power distribution between rotors and engines. The gearboxes must be highly efficient and handle unique stresses of vertical flight.

The gearbox working mechanisms in helicopters and VTOL aircraft are critical. They enable the aircraft to take off, maneuver, and land safely.

The Engine-Gearbox Relationship

The engine and gearbox work together for the best aircraft performance. They make sure the engine’s power goes to the propeller or rotor smoothly. This is important for different types of aircraft.

Turboprop Engine Gearboxes

Turboprop engines need gearboxes to slow down the turbine’s speed. This makes the propeller work better. The turboprop gearbox handles high torque well, keeping the engine running reliably. Aircraft like the C-130 use these gearboxes for top performance.

Turbofan Engine Gearboxes

Turbofan engines are found in many commercial planes. They use a gearbox to power accessories or to slow down the turbine. The turbofan gearbox is built for reliability and efficiency. It helps the engine perform well.

Piston Engine Gearboxes

Piston engine gearboxes are used in smaller planes. They adjust the engine’s speed and torque for the propeller. These gearboxes are key for good engine and propeller performance. They help the plane run smoothly.

Maintenance and Inspection of Aircraft Gearboxes

Keeping aircraft gearboxes in good shape is key to the plane’s health. Regular checks and maintenance are essential. They help gearboxes last longer and work better.

Routine Maintenance Procedures

For aircraft gearboxes, routine care includes checking lubricant, inspecting filters, and looking at gear teeth. Always follow the maker’s maintenance schedule and steps. Important tasks include:

- Checking lubricant levels and quality

- Inspecting filters for contamination

- Examining gear teeth for signs of wear

Inspection Techniques and Tools

Using the right inspection methods and tools is vital. This helps spot problems early. You can use:

- Vibration analysis to detect imbalance or misalignment

- Thermographic inspections to identify overheating components

- Oil analysis to detect contamination or degradation

Common Wear Patterns and Their Significance

Knowing about common wear patterns in aircraft gearboxes is important. Look out for signs like:

- Pitting or scoring on gear teeth

- Excessive play or vibration

- Lubricant contamination or degradation

Spotting these signs early can prevent expensive fixes. It also keeps the aircraft safe to fly.

Troubleshooting Common Gearbox Issues

Fixing gearbox problems needs a deep understanding of possible faults. A mix of methods helps find and fix issues early. This way, big problems can be avoided.

Vibration Analysis and Diagnosis

Vibration analysis is key for spotting gearbox troubles. Technicians watch for unusual vibrations to find wear or damage. They use advanced tools and software to check the data.

Oil Analysis and Contamination Detection

Oil analysis is also important for checking gearbox health. It shows wear, contamination, or damage signs. Regular checks help plan maintenance and avoid failures.

Thermal Issues and Their Resolution

Thermal problems can hurt gearbox performance and life. Overheating can damage lubricant and parts. It’s important to watch temperature and fix thermal issues fast. This might mean better cooling systems or changing how it runs.

Using these methods, maintenance teams can find and fix gearbox problems. This reduces downtime and makes aircraft more reliable.

Technological Advancements in Aircraft Gearbox Design

Technological advancements have changed aircraft gearbox design for the better. We’re seeing a new era in gearbox technology. This is making the aviation industry better.

The design of gearboxes has evolved a lot. This includes better materials, less noise, and more efficiency. These changes are key for the future of flying, making planes work better and last longer.

Material Innovations

New materials and ways to make them have helped gearbox technology a lot. Advanced composites and alloys make gearboxes stronger and lighter. For example, carbon fiber reinforced polymers (CFRP) make planes more efficient. “The use of advanced materials has been a game-changer in gearbox design,” say experts.

Noise Reduction Technologies

Technologies have also improved to reduce noise from gearboxes. New designs and materials help cut down on noise. Techniques like profile modification and

Efficiency Improvements

Efficiency in gearbox design has also seen big improvements. This includes better gear shapes and lubrication systems. These changes mean less energy loss and better efficiency. “Efficiency is key to the future of aviation,” say leaders.

Digital Monitoring Systems

Digital monitoring systems have changed how we maintain and use gearboxes. Advanced sensors and tech let us track gearbox performance in real-time. This means we can do maintenance before problems start, cutting down on downtime. This digital leap is a big step forward, making gearboxes more reliable and safe.

Conclusion: The Future of Aircraft Gearbox Technology

As we wrap up our look at aircraft gearboxes, it’s clear that the future is bright. New advancements and innovations will shape gearbox technology. These changes will make aircraft better in performance, efficiency, and safety.

The future looks promising with breakthroughs in materials, noise reduction, and efficiency. Understanding aircraft gearboxes is key to grasping modern aviation’s complexities. With ongoing innovations, the industry will see better gearbox designs. This will lead to more reliable and efficient flying.

FAQ

What is the primary function of an airplane gearbox?

An airplane gearbox’s main job is to send power from the engine to the propeller or rotor. It adjusts the speed and torque to make the plane perform better.

What are the different types of aircraft gearboxes?

There are several types of aircraft gearboxes. These include main reduction gearboxes, accessory gearboxes, and tail rotor gearboxes in helicopters. Each type has its own role.

What are the key components of an aircraft gearbox system?

An aircraft gearbox system has several key parts. These are gears, bearings, lubrication systems, and housing structures. Together, they help transmit power efficiently and control it well.

How do gearbox working mechanisms vary across different aircraft types?

Gearbox mechanisms differ in various aircraft, like commercial airliners, military planes, and helicopters. Each type has its own needs and features.

What is the significance of the engine-gearbox relationship in aircraft design?

The engine and gearbox relationship is very important in aircraft design. Different engine-gearbox combinations exist, such as turboprop, turbofan, and piston engine gearboxes. Each has its own special traits.

What are the common issues that can occur in aircraft gearboxes?

Aircraft gearboxes can face problems like vibration, oil contamination, and thermal issues. These can be found and fixed using methods like vibration analysis, oil analysis, and thermal monitoring.

What advancements have been made in aircraft gearbox design?

Aircraft gearbox design has seen big improvements. These include new materials, noise reduction tech, better efficiency, and digital monitoring systems. These advancements have made gearboxes more reliable and efficient.

How often should aircraft gearboxes be maintained and inspected?

Aircraft gearboxes need regular maintenance and inspections. The frequency and type of maintenance depend on the gearbox and aircraft type.